Hair Tensile Property Test

- KIWITA

- Jan 15

- 3 min read

Updated: Jan 18

Inspection, Testing, and Evaluation Results Report

September 7, 2020

To:

APA Corporation Co., Ltd.

From:

Consumer Science Research Institute Co., Ltd.

20F, Edobori Center Building2-1-1 Edobori, Nishi-ku, Osaka 550-0002, Japan

TEL: (06) 6445-4670 FAX: (06) 6445-4671

We hereby report the inspection, testing, and evaluation results of the submitted samples received on March 5, 2020.

Approved by / Test Supervisor:

Asano Nakagawa

1. Test Samples

Three (3) shampoo products (see Photo 1)

Breakdown:

UMO Concentrated Solution – Shampoo without addition

UMO Concentrated Solution – Shampoo containing 1%

UMO Concentrated Solution – Shampoo containing 5%

2. Test Hair Tresses

No.1: Damaged hair, blank

No.2: Damaged hair, shampoo without UMO concentrated solution, treated 10 times

No.3: Damaged hair, shampoo containing 1% UMO concentrated solution, treated 10 times

No.4: Damaged hair, shampoo containing 5% UMO concentrated solution, treated 10 times

(Photo 1)

3. Purpose of Test Request

Measurement of hair tensile properties

Observation of hair surface using an electron microscope

Note:Publication of all or part of this report in other materials requires prior approval from our company.

4. Test Results

■ Pretreatment

<Pre-washing>

Commercially available untreated hair tresses (black hair, 30 cm / 10 g) were treated as follows:

Immersed in a 1% sodium laureth sulfate aqueous solution for 1 minute, rinsed with warm water at 40°C for 2 minutes, and excess moisture removed using paper wipes.

Dried using a hair dryer for 7 minutes.

<Preparation of Damaged Hair>

Hair was immersed for 20 minutes in a solution prepared by mixing 3% aqueous ammonia and 3% hydrogen peroxide at a 1:1 ratio in a water bath maintained at 40°C (bath ratio 1:30).

Hair was rinsed with warm water for 2 minutes, excess moisture removed with paper wipes, and dried with a hair dryer for 7 minutes.

The above steps (1)–(2) were repeated three consecutive times.

<Test Product Treatment> (For No.2–No.4)

Damaged hair tresses were immersed in warm water and excess moisture removed using paper wipes before treatment.

For one hair tress (approx. 10 g), 3 g of the test shampoo provided by the client was evenly applied by hand over the entire tress, allowed to sit for 2 minutes, then thoroughly rinsed with warm water until foam was completely removed (approx. 2 minutes). Excess moisture was removed using paper wipes.

Hair was dried using a hair dryer for 7 minutes.

The above steps (1)–(2) were repeated 10 times.

Note:Publication of all or part of this report requires prior approval from our company.

(1) Hair Tensile Property Measurement Test

(Method)

After test product treatment, hair tresses were conditioned for at least 24 hours under the following measurement conditions.

With the hair fixed at both the root and tip ends, tensile force was applied at a speed of 60 mm/min, and the load at the point of breakage was measured.

Measurement Conditions:

Room temperature: 20°C ± 5°C

Relative humidity: 65% RH ± 10%

Measurement Instrument:

Tensile testing machine (Shimadzu Corporation)

(Results)

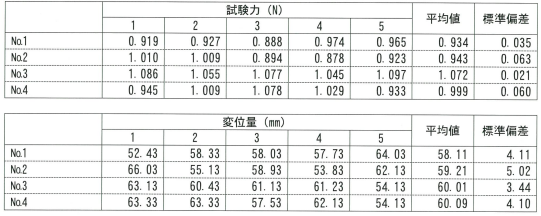

Measured values are shown below.

Terminology:

Test force: The load applied at the point where the hair breaks.(1 N ≈ 0.102 kg)

Displacement: The length the hair elongates before reaching the breaking point.

(2) Observation of Hair Surface by Electron Microscopy

(Method)

Hair strands were randomly selected from each treated hair tress as observation samples and mounted on the sample stage in a lightly tied state with cross-sections exposed.

The prepared samples were observed using an electron microscope, and two images per treated hair tress were captured.

(Results)

Attached separately.

End of Report

Note:Publication of all or part of this report requires prior approval from our company.

Consumer Science Research Institute Co., Ltd.

Note: This paper is translated from the following URL. The content is provided for reference on the scientific research of the raw material only. Whether APA raw materials are used or not, we hope this research will help increase understanding and awareness of body minerals.

Comments